MMS • RSS

Article originally posted on Data Science Central. Visit Data Science Central

In the twentieth century, oil was the most valuable resource – but not anymore. In today’s digital age data is the new oil. It will play a similar, perhaps bigger role, becoming a game changer that provides power in terms of information and competitive advantage through actionable insights. Some experts call it a commodity, but an ever-increasing one. The data can be exploited to design innovative products, build new business models, improve operational efficiencies, and reimagine customer journeys. We believe that asset-intensive industries have a unique opportunity to create more value by generating energy (read insights) from enormous data across the value chain.

Industrial Internet of Things (IIoT) has fueled a revolution powered by data and analytics. The rate at which data is being captured is amazing, Zettabyte is a commonly used term among data scientists and administrators. A recent Cisco report suggests that data from devices connected to the internet will reach 403ZB a year by 2018, up from 113.4ZB a year in 2013. Of that, nearly 40% would be generated by factories and industries through IIoT. Newer production systems even come with over 30,000 sensors to fetch range of data streams from various equipment. Natural resources, metal, mining , oil and gas, chemicals, and other process industries are reigning in automation and boosting the generation of data. For example, mining giant Rio Tinto generates 2.4 TB of data every minute.

Apart from IIoT, business applications such as ERP, EAM, CRM, MES, HRMS, and finance systems capture a lot of business-process data. There is a ton of data generated and captured every minute across the value chains. The key is not about the volume, velocity, or variety of the data, but rather of the business value we can extract from it. The data by itself will be useless; organizations must devise smart ways of extracting actionable insights. We believe that data strategy comes first in chalking out roadmap for digital transformation. Identifying the data points, defining metrics, and designing visualizations is critical for success.

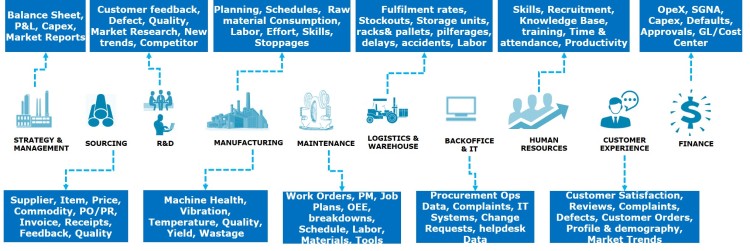

Following image depicts sample data points and metrics across asset-intensive value chains.

In process industry, data can be leveraged as the most useful resource. However, no clear use case or strategy for data, will only lead to countless hours of mindless data crunching with futile results. A digital journey must have a data vision – what can be done with the data? This vision must be driven by the business needs and translated into impactful use cases and applications. Some representative yet critical use cases surrounding data include:

- Asset/Equipment – Enhance asset reliability through predictive analytics and simulation using digital twins

- Product – Design high-quality and innovative products

- Production – Leverage data from IoT sensors to monitor pumps, pressure and vibration levels, and process parameters to optimize the production process

- Quality – Quickly understand how changes in machine parameter and procedures can affect product quality using predictive models

- Supply chain process – Gain visibility to improve cycle time, efficiency, order fulfillment, and Supply chain health

- Customer – Understand the needs of customer to devise “non-price” ways of competing in the market, analyze customer journeys, and reimagine the customer experience

- Supplier – Understand supplier performance and develop the best sourcing strategies and supply planning

- Finance – Unlock potential savings and process inefficiencies in the maze of corporate financial transactions

- Environment – Understand real-time environmental factors and design product and fulfillment strategies, smart technology to optimize energy consumption

- Regulatory – Monitor processes in real time and avoid breaching of any regulatory requirements

- Economy – Get real-time updates on economic and political events and impacts on commodity prices, business, taxes, new laws, etc. and adapt business strategies.

Data is driving digital transformations. Leading organizations have realized the importance and have undertaken initiatives to harness the power of data, for example:

- Dow Chemical’s uses sensors and GPS technology to safely transport 7000 shipments everyday globally and reduces any transportation-related risks

- BASF uses computer modeling using the underlying physicochemical processes data to reduce batch times by 30% resulting in significant energy savings

- Air Liquide provides a digital eye-wear integrated to helmet to its maintenance employees, which provides them vital information such as maintenance instructions, information in real time and alerts the worker in case of any safety incidents

- DuPont Photovoltaics Solutions and Envision have announced that they will collaborate on the development of a predictive analytics solution designed to identify and eventually mitigate degradation in PV modules.

There are numerous examples and use cases to learn from. Data capture and storage is a critical first step – but that alone isn’t enough. The key is not about data storage rather exploiting data for creating business value by – understanding impact of data on business, deploying right IIoT solutions, upgrading machine and equipment, building analytical capabilities, implementing modern ways of managing master data, and so on. Focusing on “domain and data-centricity” is a must and industry leaders are putting together programs for efficient generation of information energy that will drive the business of the twenty-first century.

There is no doubt, data analytics will determine future for many businesses. Are you ready to harness the power of data to transform your value chain? Write to us to learn more.

“Numbers (data) have an important story to tell, they rely on you to give them a clear and convincing voice.”

—Stephen Few

By:

Amit Supe (APICS CSCP, SMRP CMRP),

Abhisek Nanda (APICS BSCM, SMRP CMRP)

The original article was published here.